Description

Description

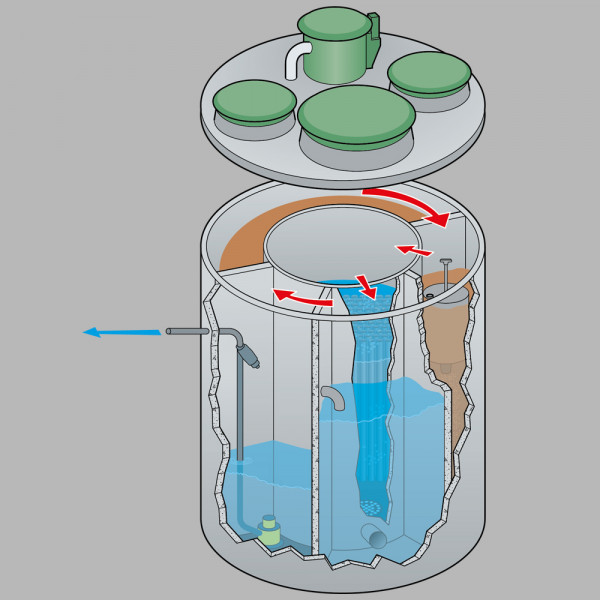

The Oasis 2000 model is the most extensively used and proven wastewater system on the New Zealand market today. Housed in a single concrete tank with adequate capacity to treat waste water for up to 10 persons. The Oasis Clearwater system incorporates five chambers to effectively process and treat your home wastewater, turning it back into a clear, odourless liquid that can be reused on-site (subject to local authority approval) for applications such as watering trees and other planted out areas.

Accredited Performance

In the OSET NTP Trial 10 The Oasis Series 2000L system was tested at 1,000 litres/day (equivalent to servicing a 3-bedroom 5 to 6 person household) over an 8 month (35 week) period where the Oasis system achieved a performance level of 100% for BOD5 and 100% for TSS based on the full set of 37 test results in weeks 9 to 35, with no results exceeding the maximums.

Features

- The Oasis Clearwater 2000 is an aerated treatment tank system which uses totally natural biological processes to treat the waste water. It consists of a set of 5 chambers which perform various treatment processes on the waste stream.

- The Oasis uses high quality components, and all internal chambers are solid concrete for durability.

- The Oasis 2000 is quiet and economical in operation.

- The Oasis Clearwater 2000 has a total running cost (Electricity) of around 50 cents per day or $182.00 per year not including service costs which is not bad when you consider that the average fixed wastewater charges in Auckland are $264.00 per year and then you get charged based on metered water usage on top of that.

- The Oasis systems are a compact sewage treatment system housed in one concrete tank. It is intended to treat domestic waste water from single households with adequate capacity to treat waste water for up to 10 people. They are simply installed in-ground and then connected to the household plumbing system and to the power to run the air blower, electronic alarm control unit and the irrigation pump. The system is then ready to irrigate to an area usually approved by local council.

The Oasis Clearwater 2000 units are producing water to the “ADVANCED SECONDARY” level – This is the most common unit that we sell as it produces a very high quality discharge suitable for sites that are near a waterway or where sites are environmentally sensitive.

Care and Maintenance

It is important to realise that on-site waste water systems require regular inspection and maintenance to ensure that they function efficiently and effectively and the system must be operating correctly to ensure that the health of your family and the community are protected at all times.

Absolute Concrete can provide you with options for an ongoing maintenance program for your peace of mind. This will ensure that your system continues to operate as designed, warranties are protected and the unit will continue to function correctly in the long term. It is useful however for you to familiarise yourself with the system so that you understand the general operation of the unit but it is likely that council will need a maintenance contract in place with any secondary system as part of your building consent.

Chamber1. Wastewater from the home is piped to the primary chamber where anaerobic and other oxidising bacteria break down suspended solids. This chamber also receives activated aerated sludge from the clarifying chamber that stimulates the bacteria and enhances the level of solids digestion.

Chamber 2. Wastewater is able to flow freely from the first primary into this chamber where it can mixes with the partially treated wastewater and prepares it for the processes that follow.

Chamber 3. Fluid is decanted from the second chamber through a proprietary effluent filter to eliminate the passage of grease and floating matter. Oxygen is dispersed through this chamber via a fine air diffuser powered by an air blower. The chamber contains submerged Bioblock media with a surface area of 80 square metres where a high level of aerobic treatment takes place.

Chamber 4. Liquid from the aeration chamber flows into the clarifying chamber. Any suspended particles to settle to the bottom where they are drawn back via a venturie system and returned to the primary chamber for further processing.

Chamber 5. The treated wastewater flows to the pumping chamber where it is pumped out in dosed loads to a dispersal field that is often designed to irrigate gardens, shelter belts and other planted areas.

Land application systems vary according to individual situations and are most commonly made up of pressure compensating dripper line but can also be in the form of surface sprinklers, subsurface irrigation, sand filters or other innovative systems. Your local council will decide this.

Excavation Dimensions and Relevant Facts

Depth Approx. 2400mm Width Approx. 3000mm Invert below ground 500mm or 1,850mm from base (Options for more fall are available if required).

Tank/System Weight 7.5 tonnes Diameter 2.5m

Total operating volume 6,860 litres Total holding capacity 9,400 litres

Average operating performance on tank water 10 people at 160 l/person (1,600 litres)

Owners/Tenants Responsibilities

- Absolute Concrete can suggest a maintenance person in your area if required, or you could contact your local council for a full list of licensed service personnel.

- The owner/tenant of the property should ensure safe passage for the Service Technician. Any animals that may pose a danger to the service technician should be locked up or penned during servicing.

- The owner/tenant should provide a key for the Service Technician if there are any locked gates which prevent entry to your property.

- The owner/tenant should ensure that the area around the Oasis System is kept neat and tidy at all times.

- The owner/tenant should monitor the final output filter in between services and clean if necessary.

- The service technician will clean the filter every to six months depending on the contract, this is critical to ongoing performance of any secondary system.

- The owner/tenant should ensure prompt payment of any service or repair accounts.

- The owner/tenant should not allow painters / cleaners etc.. to dump paint chemicals etc.. into the drains whilst working on site and any household cleaners/chemicals should be used in moderation to avoid harming the good bacteria in the system.

- If you have any further questions please contact us directly on 09 431 2211